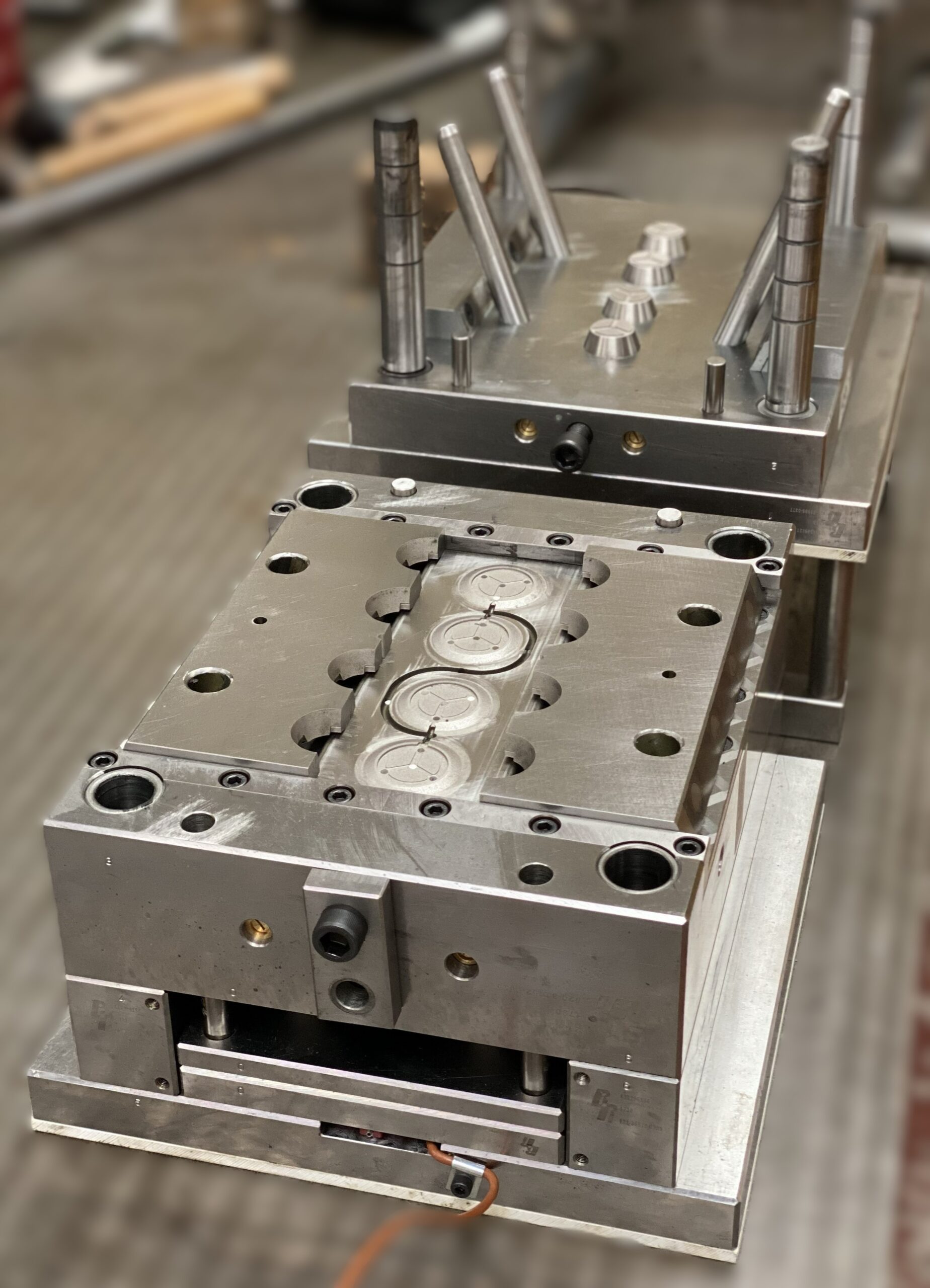

Injection Mould Tooling

Our in-house tooling experts will take care of all the mould tool needs of your project, from start to finish.

Whether it is a simple prototype tool or a complex multi-cavity serial production tool, a brand new tool or a transfer tool, we will handle it all and give you a successful, cost-effective outcome.

New tools

Our expert tooling project managers will handle every step of the mould tool design and build for your project, including:

- component DFM review

- proposal and appraisal of tool design options

- cost-benefit analysis of tool options eg. payback on more cavities, hot vs cold runner, or automation features

- competitive tendering of toolmaker

- review and sign-off of detailed tool design

- monitoring of tool build

- tool trialling and acceptance sign-off from toolmaker

- tool production trials at Global Filters

- technical support and customer liaison throughout

We use our own toolroom to build small prototype and serial production tools.

For larger, more complex or higher volume tools, we partner with a small number of carefully selected, trusted and proven toolmakers, located in the UK and China. We deal with them all directly, not through agents, to ensure quality and delivery.

Tool transfers

We love to make new tools, but if you have an existing mould tool you can transfer to us, that’s great – we have successfully adopted suites of up to 25 tools from other moulders, and had them delivering conforming parts in just a few days to keep our customers’ production lines running.

We give each tool a full health-check and service on arrival, and will discuss and agree your tool trial and process validation requirements in advance.

So whether it is a brand new tool, or a tool transfer, you can trust Global Filters to deliver.